Prestressing Anchorage System for PT Bars & Steel Strands

What is Prestressing Anchorage System for PT Bars & Steel Strands?

Complete prestressing anchorage system for PT bars and steel strands in mining and construction. Includes anchor plates, wedges, and couplers. Compatible with various rock bolt and cable bolt applications. ISO certified ground support equipment manufacturer.

Prestressing Anchorage System

Product Overview

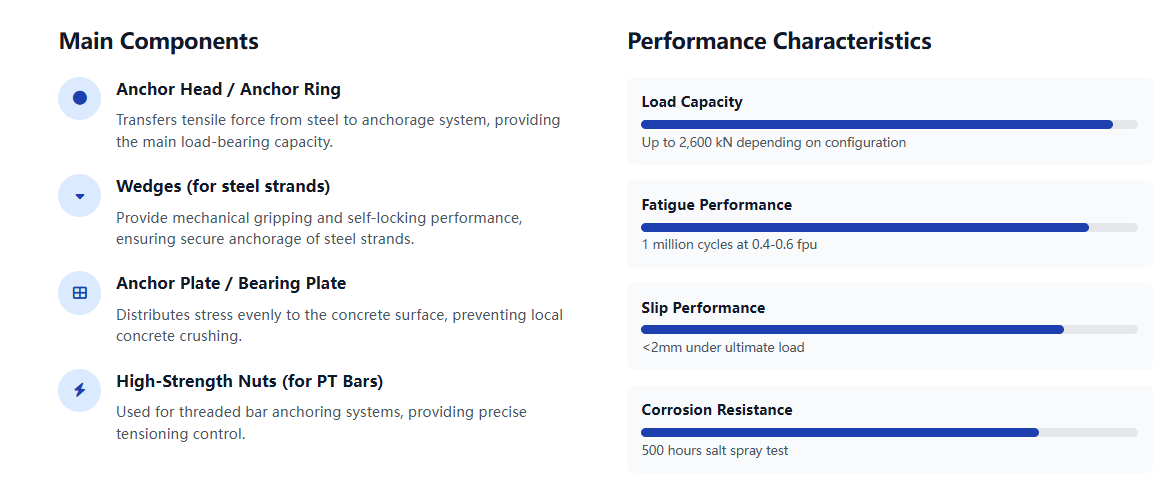

Prestressing anchorage is a critical load-transfer component in prestressed concrete and post-tensioning systems. It is designed to securely anchor prestressing steel—such as PT Bars or steel strands—and transfer tensile forces efficiently into the concrete structure.

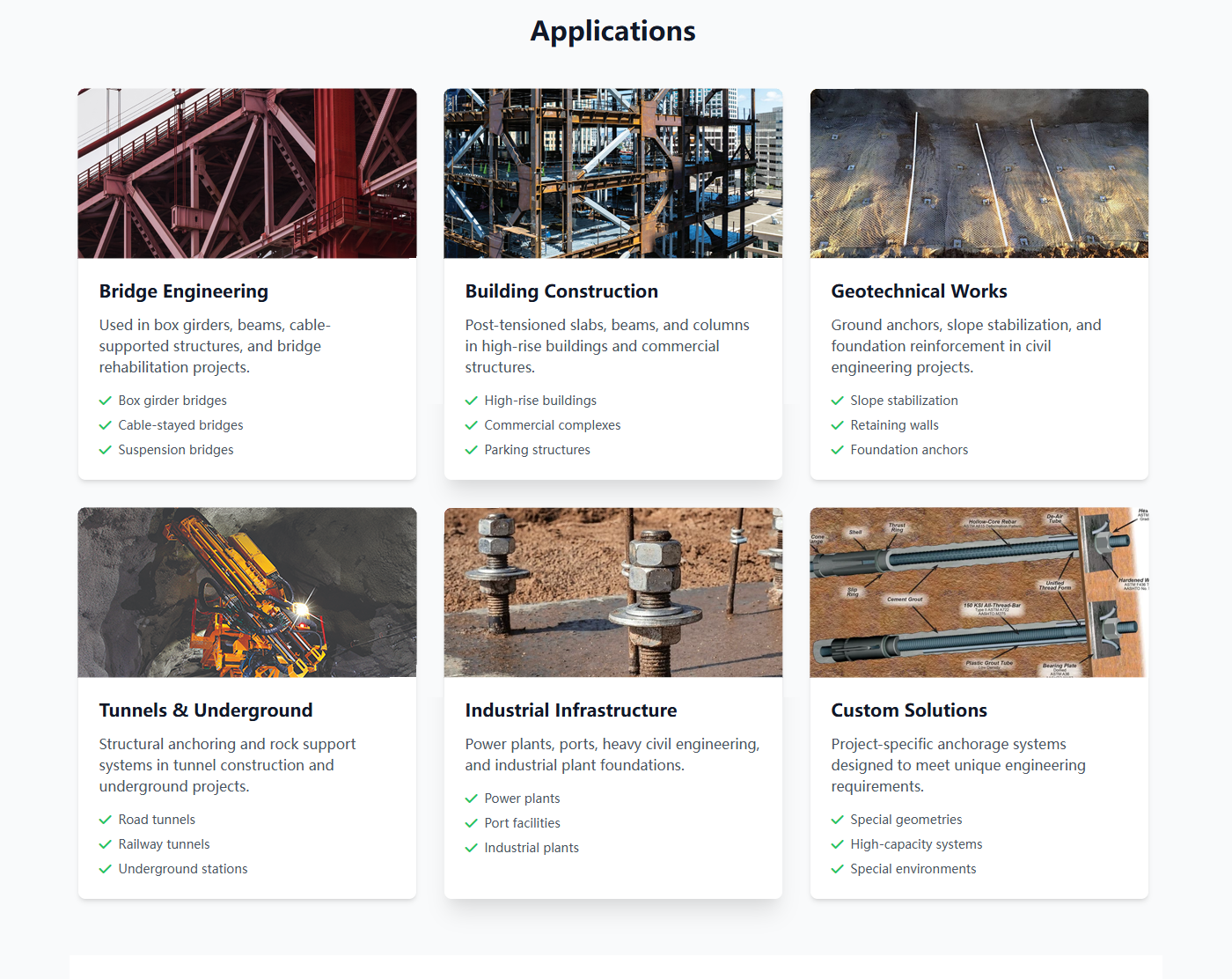

The anchorage system ensures stable force locking after tensioning, minimal slip, and long-term structural safety. It is widely used in bridges, buildings, geotechnical anchoring, tunnels, and heavy infrastructure projects.

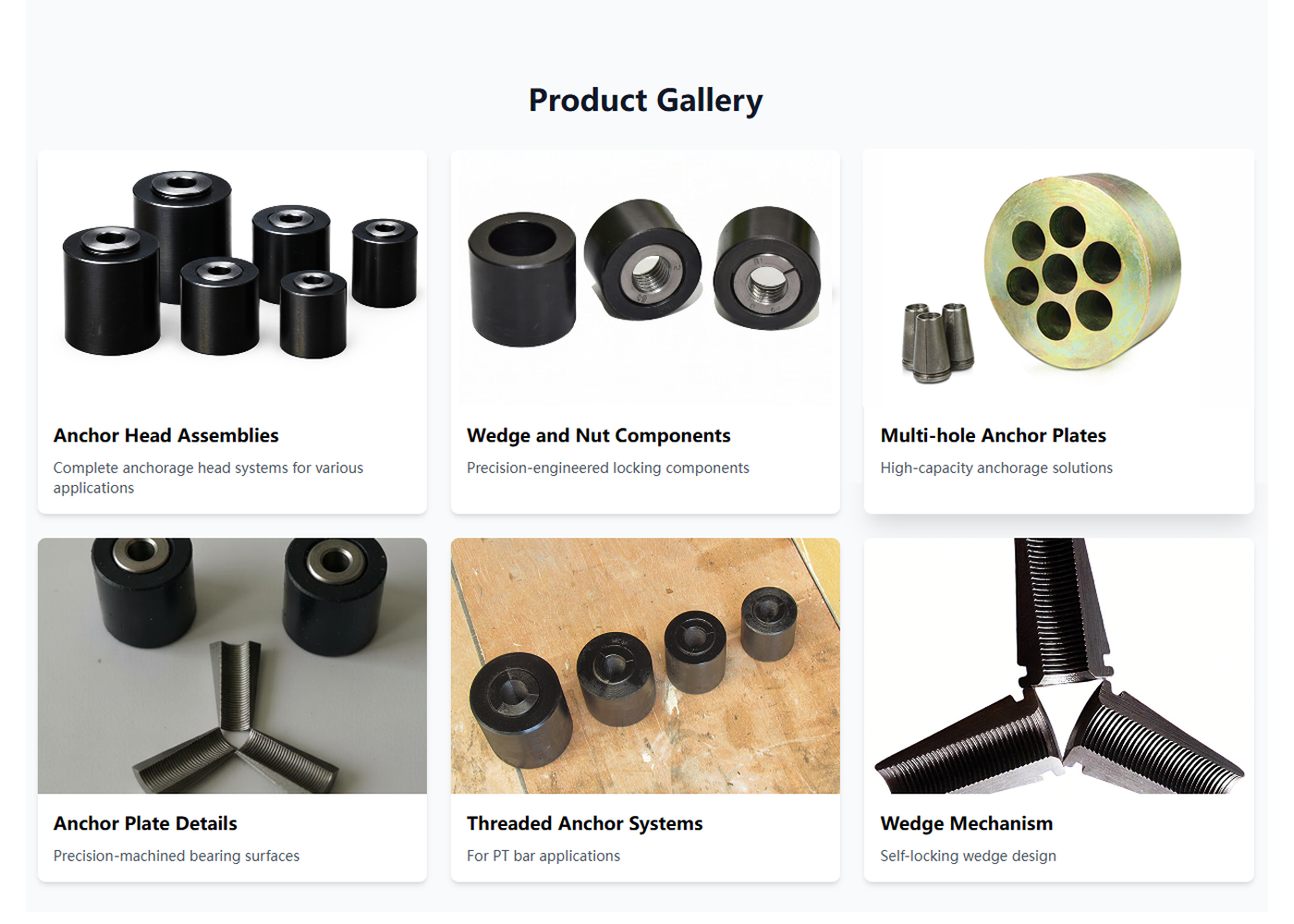

| Key Applications: •Bridge construction and rehabilitation •High-rise building structures •Geotechnical slope stabilization •Tunnel and underground construction •Industrial plant foundations | Product Range Single-hole anchorages Multi-hole anchorages (2-31 holes) Wedge-type anchorages Threaded anchorages for PT bars Custom-designed solutions |

|---|

Key Benefits

High Anchorage Efficiency Designed to achieve ≥95% anchorage efficiency with reliable load transfer and minimal slip under working loads. | Secure Mechanical Locking Wedge or threaded anchoring ensures stable force retention after tensioning, providing long-term structural safety. | Excellent Fatigue Resistance Suitable for cyclic loads and long-term service life in demanding applications like bridges and heavy infrastructure. |

|---|---|---|

| Strong Compatibility Fully compatible with PT Bars or standard prestressing steel strands, providing flexibility in system design. | Customizable Configurations Single-hole, multi-hole, or project-specific anchorage solutions tailored to meet exact project requirements. | Corrosion Protection Black oxide, galvanized, or special coating options available to protect against corrosion in harsh environments. |

Technical Specifications

| Applicable Steel | PT Bar / Steel Strand | Φ12.7, Φ15.2 mm or custom diameters |

| Anchorage Type | Wedge-type / Threaded | Based on steel type and application |

| Material | High-strength alloy steel | Heat-treated for optimal performance |

| Anchorage Efficiency | ≥95% | Standard requirement for safety |

| Surface Treatment | Black / Galvanized / Coated | Corrosion protection options |

| Standards | GB / ASTM / EN | Manufactured to international standards |

| Hole Count | 1-31 holes | Single and multi-hole configurations |

| Working Load | Up to 2,600 kN | Depending on configuration |

Quality Assurance

- 100% material traceability

- Comprehensive performance testing

- ISO 9001 quality management

- Third-party certification available

- Full documentation package

Frequently Asked Questions

Can you supply anchorage systems together with PT Bars or steel strands?

Yes, complete prestressing systems including anchorage, bars/strands, and accessories are available. We can provide matched systems to ensure optimal performance and compatibility.

Do you support production based on drawings or project specifications?

Yes, customized anchorage systems can be manufactured according to drawings or technical requirements. Our engineering team can assist with design optimization and performance verification.

Do you provide third-party testing reports?

Yes, SGS, BV, or other third-party inspection reports can be provided upon request. We also offer factory acceptance testing and witness testing services.

What is the lead time for standard and custom products?

Standard products: 2-4 weeks

Custom products: 4-8 weeks

Urgent orders: Available with priority production scheduling

What quality certifications do you hold?

We are ISO 9001 certified and our products meet international standards including GB/T 14370, ASTM A416, EN 13138, and ISO 15630.

Interested in this product?

Get in touch for more information, pricing, or custom requirements.